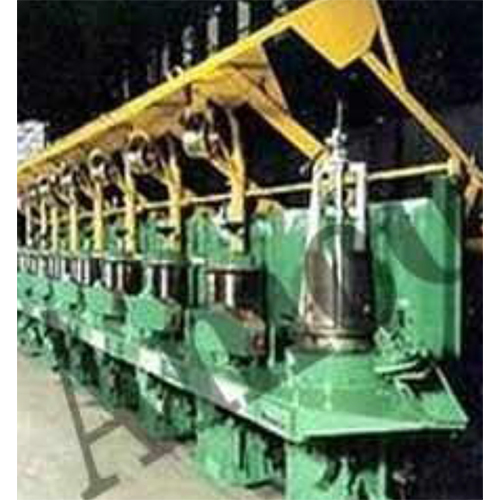

Straight Line Wire Drawing Machine

Straight Line Wire Drawing Machine Specification

- Condition

- New

- Application

- Industrial

- Voltage

- 220 Volt (v)

- Function

- Semi-Automatic

- Product Type

- Straight Line Wire Drawing Machine

Straight Line Wire Drawing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 10 Days

About Straight Line Wire Drawing Machine

We are engaged in offering a superior range of straight line wire drawing machine to our clients, which is especially designed by our experts operate continuously. The first block of our range is facilitated OTO type for wire accumulation, allowing and for the removal of any rod, snarl or changeover of coils at feeding end. There is a VFN system on OTO block that keeps uniform tension of wire passing over with on jerks. Furthermore, for accurate control of air pressure on sensor arm, the each block of our range is equipped with pressure regulating valves and gauges. It is also provided with separate manifolds for water to drums and dies with regulating valve on each block.

| Machine Model | MTS 610/9 Wire Drawing Machine with Sensor and Dancer Arm Speed |

| Block Diameter | 610 mm |

| No. of Blocks | 9 |

| Last Block | Standard |

| Surface Hardness | More than 65 HRC |

| Wire Inlet | Ceramic Coating |

| Wire Exit | From Block 1 |

| Maximum Pull on 1st Draft | From block 6,7,8,9 |

| Drawing Range | 730 N/mm2 |

| Die Size | 5,5 mm max. |

| Inlet - Outlet | 1,60 to 1,80 mm |

| Rotating Die Box | 43 x 30 mm |

| Reduction Per Draft | On all Block |

| Final Drawing Speed | 16 to 24% (Limited to Speed only) |

| Main A.C. Motor Power | 20 m/sec at Constant Torque |

| Insulation Class H | 9 x 45 kW - 2300 rpm |

| Cooling Fans Motor Power | 2 x 40.4 kW - 1310 rpm |

| Enclosure Type IP | 23 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Drawing Machine Category

Wet Drawing Machine

Minimum Order Quantity : 1 Piece

Condition : New

Application : Industrial

Voltage : 220 Volt (v)

Product Type : Wet Drawing Machine

Function : SemiAutomatic

Rigid Stranding Machine

Minimum Order Quantity : 1 Piece

Condition : New

Application : Industrial

Voltage : 220 Volt (v)

Product Type : Rigid Stranding Machine

Function : SemiAutomatic

OTO Type Wire Drawing Machine

Minimum Order Quantity : 1 Piece

Condition : New

Application : Industrial

Voltage : 220 Volt (v)

Product Type : OTO Type Wire Drawing Machine

Function : Automatic,SemiAutomatic

Wire Galvanizing Plant

Minimum Order Quantity : 1 Piece

Condition : New

Application : Industrial

Voltage : 220 Volt (v)

Product Type : Wire Galvanizing Plant

Function : Automatic,SemiAutomatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry